LANDPACK has rich experience in the field of providing hardware packing solution.

Normally the vibrator would be the one of counting system for hardware.

How does the hardware vibrator work?

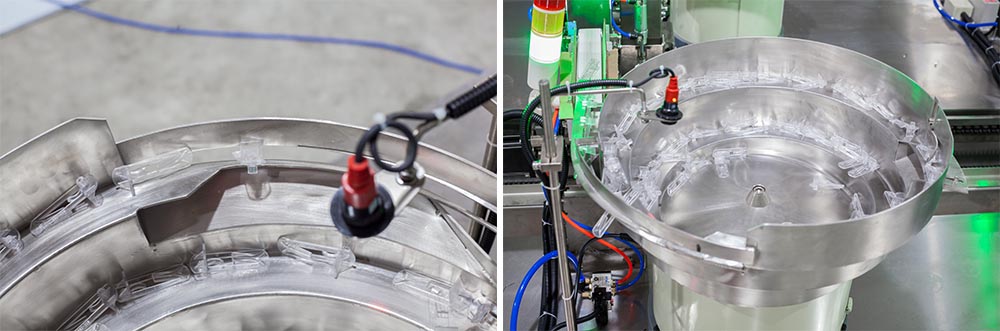

The vibrating plate is an automatic directional sorting feeding equipment. The composition of the vibrating plate: hopper, chassis, controller, linear feeder.

A vibrating plate is a force that generates a directional frequency when a vibration motor is used as a power vibration motor. As long as the vibrating plate is regarded as a kind of inclined plane, and then the physical force analysis of this inclined plane is carried out, you can easily understand his It works.

When the electromagnetic coil of the vibrating plate is in operation, the inclined surface will have a slight up and down amplitude due to the electromagnetic attraction force. Adjusting the working frequency and clearance of the vibrating plate can achieve smooth operation. The principle of vibrating electromagnet: The electromagnet is used to generate an alternating magnetic field. The vibrating device is an iron piece suspended in front of the electromagnet. When the signal passes through the electromagnet, the electromagnetic field of the electromagnet will change, so that the iron piece vibrates and sounds.

The working principle of the vibrating plate: There is a pulse electromagnet under the hopper, which can make the hopper vibrate vertically. Due to the inclination of the spring sheet, the hopper will vibrate around its vertical axis. The parts in the hopper rise along the spiral track until they are sent to the discharge port based on the vibration.

The automatic feeding vibrating plate is a feeding equipment for automatic directional sorting. The purpose of its work is to automatically and orderly align the disordered workpieces in an orderly and accurate manner to transport them to the next process through vibration. In addition to satisfying product sorting, it can also be used for sorting, testing, counting and packaging. It is a modern high-tech product.

The automatic feeding vibrating plate contains material hopper, chassis, controller, linear feeder and other supporting frame components. There is a pulse electromagnet under the hopper of the automatic feeding vibrating plate, which can make the hopper vibrate vertically. Due to the inclination of the spring sheet, the hopper will vibrate around its vertical axis. The parts in the hopper rise along the spiral track until they are sent to the discharge port based on the vibration. The hoppers of the automatic feeding vibrating plate are divided into five types: cylindrical hopper, screw, wire hopper, conical hopper, and equal line hopper; the chassis has four types: positive-pull chassis, side-pull chassis, piezoelectric chassis, and precision chassis; controller It is divided into five types: ordinary controller, polarized controller, frequency modulation controller, belt slow start controller, and digital display frequency modulation controller; linear feeders can be customized according to customer needs. Various types of linear feeders can also be customized according to products Request to order.